A basic guide to hydraulic oil

Hydraulic oil is a non-compressible fluid that is used to transfer power within hydraulic machinery and equipment, and lubricates system components. It is crucially important to regularly check and maintain a system’s hydraulic fluid.

Hydraulic oil can be synthetic or mineral based. Other chemical additives are often added to hydraulic fluid to maintain or improve performance of the oil and the equipment within the hydraulic system. The additives can help to prevent corrosion, rusting and water contamination. It is critical the appropriate oil is chosen for each system. Using the incorrect oil can lead to performance issues and potentially system and component damage.

Additives may include anti-freeze for oils that are been used in harsh, cold environments. In the event of high temperatures, which in turn would lower the oil’s viscosity and increase the risk of leakages, additives may be added to maintain a suitable viscosity for the system being used.

If hydraulic fluid is being used in a high pressure condition, heavy-duty oil is necessary. Heavy-duty hydraulic oil often contains additives that prevent wear.

Biodegradable and environmentally-friendly oils are excellent for those working in sectors that may pose a potential risk of oil spills or leak, and thus environmental contamination. The oils, which are made of rapeseed and other vegetable oils, are also great for businesses with sustainability awareness and targets.

Hydraulic oil life

It’s important to maintain healthy hydraulic systems and components, a crucial part of this is looking after your hydraulic oil.

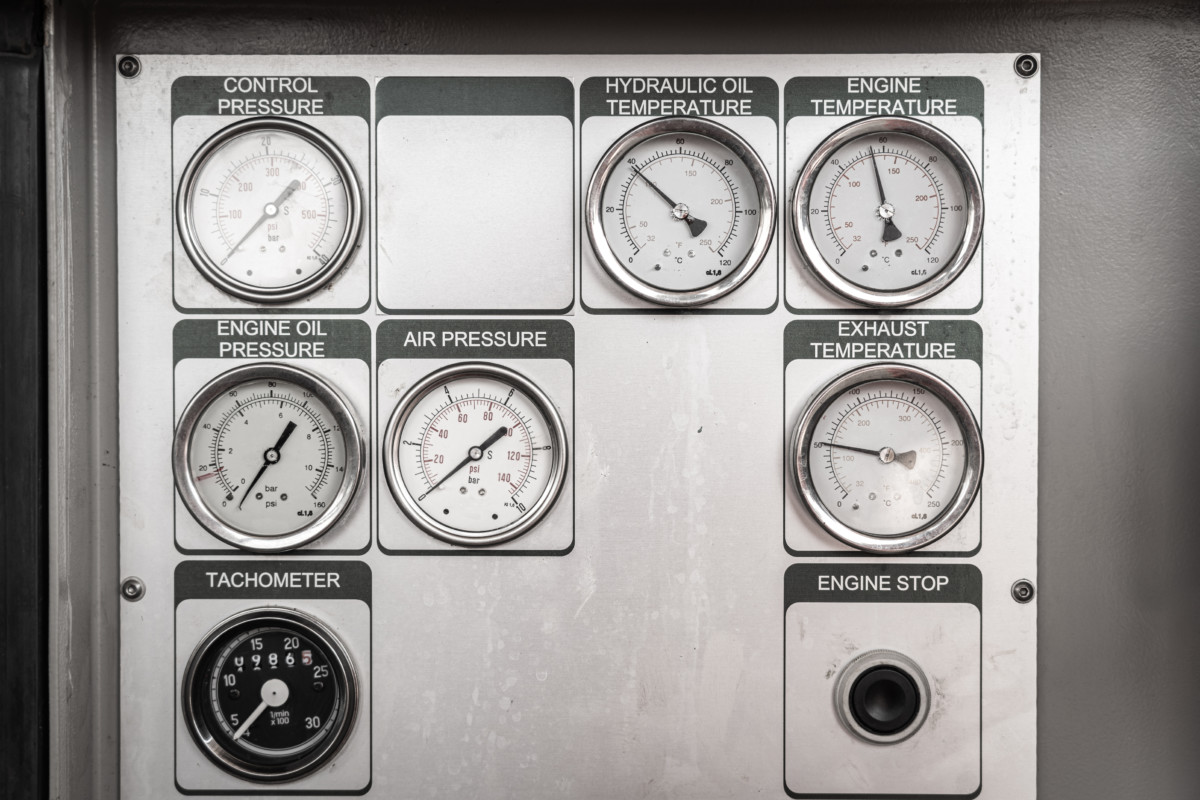

Modern hydraulic systems are typically smaller and use less oil during operation. Pumps can also produce a lot more output, subsequently producing higher pressures. Less oil means higher fluid temperatures – which in turn, increases oxidation and thermal stress on the additives on the oil.

Several factors can influence hydraulic oil longevity including:

- Oil quality

- Working conditions

- Oil temperature

- Oxidation

- Contamination.

Within the right environment and with the correct maintenance, a high quality oil may last longer than six months.

For technical support and more information about choosing and maintaining hydraulic oil for your systems, contact Rotec via sales@rotec.net or phone 01823 348900.