One week of work experience at Rotec

Last month, we were pleased to team up with the Kingsmead School in Wiveliscombe, Somerset, to provide a work experience for one of their pupils: Harry Alcock. Harry joined our Taunton Depot for a week, to experience first-hand how Rotec operates. Under the direction of Matt Turnbull, Rotec’s purchasing manager, Harry spent time working in the Stores, Warehouse, Electrical Bay and the office learning about Mechanical Design and Website build.

Harry was in for a Health and Safety briefing on Monday morning, before spending the afternoon with our Stores Manager, where he learned the general operational principles such as booking in/out, packing and picking. The next day, Harry was actively involved in the Stores day to day activities discussed the previous day and assisted with assembling a crate for one of Rotec’s marine customers.

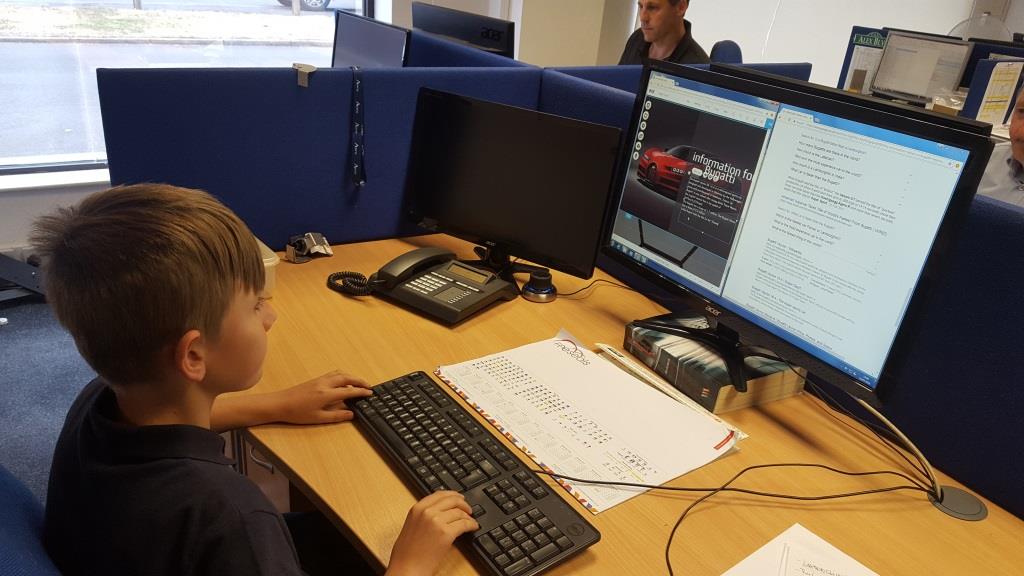

On Wednesday, Harry joined the marketing department where he was introduced to website building using the popular online platform Wix. Harry chose to create a website focused on supercars and spent the day with Rotec’s marketing executive creating a working site using best marketing practices. The website Harry created is available on: https://harrysalcock03.wixsite.com/harryssupercars

Thursday morning was spent in the warehouse hose assembly with our team of engineers, wrapping hoses for our utilities customer.

On Friday morning, Harry was back in the office, working under the guidance of Rotec’s engineering director (pictured), who taught Harry about CAD design, before moving onto assisting the stores and the warehouse in the afternoon, with their usual Friday housekeeping tasks.

Matt, who supervised and supported Harry through-out his working experience, was impressed at Harry’s work ethic, at his ability to follow instructions and his positive attitude. We would gladly welcome Harry back anytime and we look forward to the next time we are able to support the local schools with their work placements.

Author: Sarka Humpolcova

Date: 2/08/2018