IQAN tools, cables and connectors

IQAN tools, cables and connectors

For the full range of Parker IQAN tools, cables and connectors please view the BROCHURE

For the full range of Parker IQAN tools, cables and connectors please view the BROCHURE

For full range of Parker sensors please view the BROCHURE:

Application

The IQAN-ST temperature transducer belongs to the family of IQAN accessories developed to complement IQAN control systems. IQAN-ST is a 0-5V output temperature transducer for mobile hydraulic applications. This transducer is available in three interface types; G1/4 BSP, M10 and 9/16”-18 UNF SAE 6. The G1/4 BSP and M10 sensors have an integral Bosch automotive connector. The SAE 6 sensor has a short cable-mounted Deutsch connector.

The IQAN-ST has stainless steel construction for strength. The PT100 sensor uses thin film technology with internal amplification. All versions of the sensor have high pressure capability. The IQAN-ST is very robust and able to withstand heavy vibrations.

The design of the IQAN-ST has an EMI cap that separates the sensor electronics from the connector. This ensures a high level of EMI protection.

The IQAN-ST is well designed for the mobile hydraulics industry. The 3 pin integral connector is a sealed AMP Junior Power Timer (Bosch Jetronic) type. The Deutsch connector is the DT04 type. Both connectors are designed for automotive use. These connectors give the sensor IP65 protection for exposed outdoor applications. The hex of the G1/4 BSP and M10 versions of the transducer have integrated face seals to eliminate loose sealing washers. The SAE 6 sensor type has a factory installed o-ring. These features provide for easy installation and removal, even in field conditions.

For more information please view:

Application

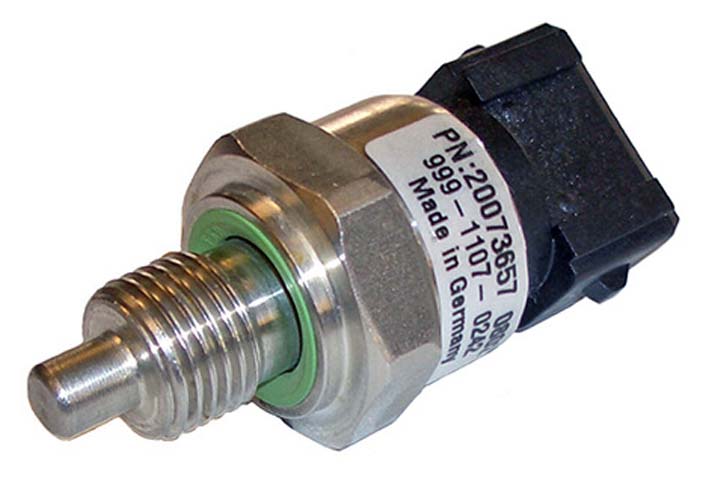

The IQAN-SP pressure transducers belong to the family of IQAN accessories developed to complement IQAN control systems. IQAN-SP is a range of 0-5V pressure transducers for mobile hydraulic applications. These transducers are available in two pressure ranges; 35 bar (507 psi) and 500 bar (7250 psi). To make the sensors suitable for mobile equipment, we have focused upon properties such as reliability, electromagnetic immunity and ease of installation.

Reliability

The IQAN-SP has stainless steel construction for strength. The sensor cells use thin film technology with no internal o-rings or fluid. The high pressure capability makes the sensor very robust and able to withstand vibration.

Electromagnetic immunity

The design of the IQAN-SP has an EMI cap that separates the sensor electronics from the connector. This ensures a high level of EMI protection.

Installation

The IQAN-SP is well designed for the mobile hydraulics industry. The 3 pin connector is a sealed AMP Junior Power Timer (Bosch Jetronic) type designed for automotive use. This connector gives the sensor IP65 protection for exposed outdoor applications.

The hex of the G1/4 BSP threaded transducer has an integrated face seal to eliminate sealing washers. These features provide for easy installation and removal, even in field conditions.

For more information please view:

Application

The IQAN-LC5-X05 is a large, coordinate joystick that incorporates ruggedness, functionality, light weight with high flexibility for mobile market applications. The unit is extremely robust, able to withstand aggressive conditions during outdoor use and in outdoor installations, including EMI, vibrations and a wide temperature range. The IQAN-LC5-X05 features a compact ergonomic design making it ideal for armrest and panel installations in mobile equipment. Fourth generation ICL4 type joysticks with N or G handles are easily replaced with the IQAN-LC5-X05.

The joystick base has an integrated Deutsch transportation connector. The handle cable may be routed completely through the non-corrosive housing. This makes field mounting of new handles, or replacing a bellow, very easy to accomplish.

All proportional output signals are of contactless Hall effect type with dual sensors to provide redundancy for high safety and reliability. The primary signal for each axis is 10%-90% of supply voltage. The corresponding secondary signal is 90%-10% of supply voltage.

For more information please view: