BFPA ‘Q’ Approved Hydraulic Hose Assemblies from Rotec – What this means for you

We are proud to be a BFPA Approved Distributor and ‘Q’ Approved for hydraulic hose assemblies – an assurance of the highest standards in fluid power safety and quality.

What Does This Mean for You?

Choosing a ‘Q’ Approved supplier like Rotec Hydraulics over non-accredited providers delivers critical benefits for your operation:

Guaranteed Safety and Reliability: Our accreditation assures you that every hose assembly is built to an industry-agreed, rigorously audited standard. This significantly reduces the risk of hose failure, injury, and dangerous fluid injection.

Highly Trained & Certified Technicians: All our hose technicians are trained and certified to the BFPA industry standard, ensuring a professional understanding of hose technology and best practice assembly techniques.

Eliminating Dangerous Practices: We are strictly audited to never partake in hazardous practices such as:

Mixing and Matching components from different manufacturers, which can compromise the integrity and safety of the assembly.

Re-ending used hose assemblies, a false economy that dramatically increases the risk of failure.

Reduced Downtime and Increased Efficiency: Quality products and expert assembly mean less unexpected failure, less downtime for your machinery, and greater productivity for your business. The ‘Q’ stands for Quality, Efficiency, and Safety.

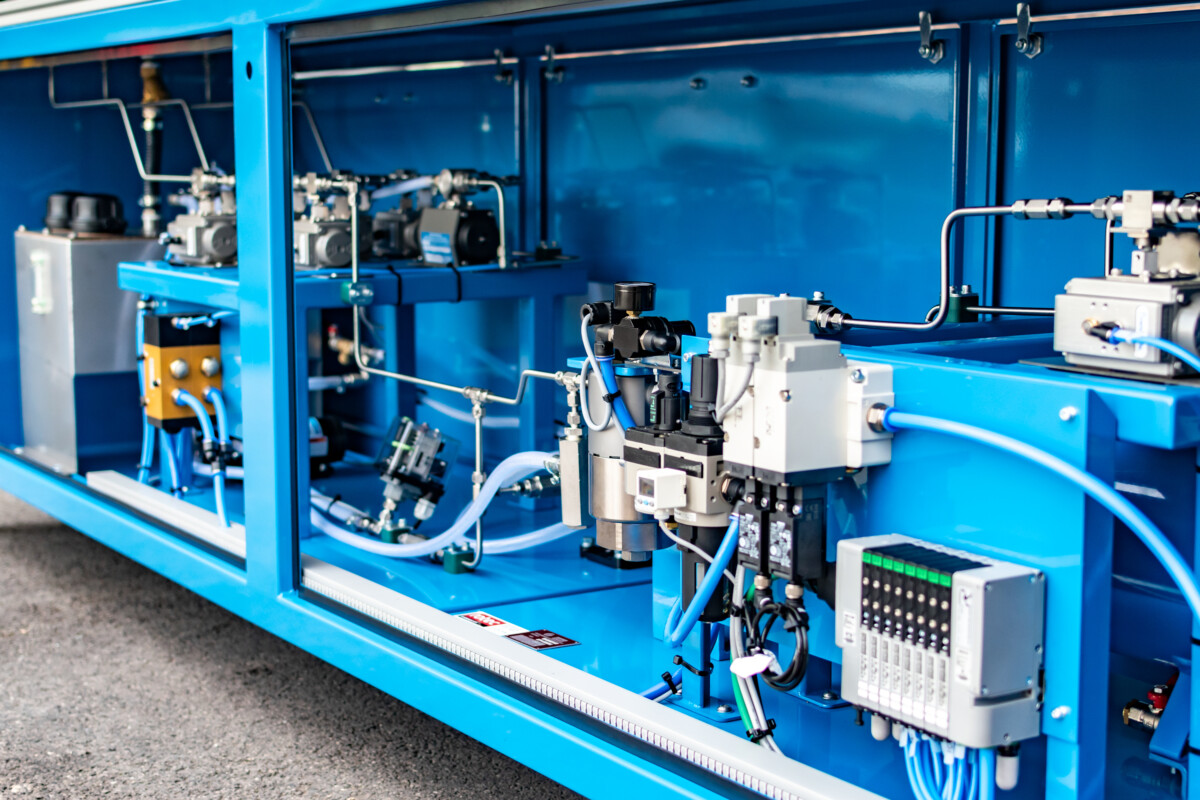

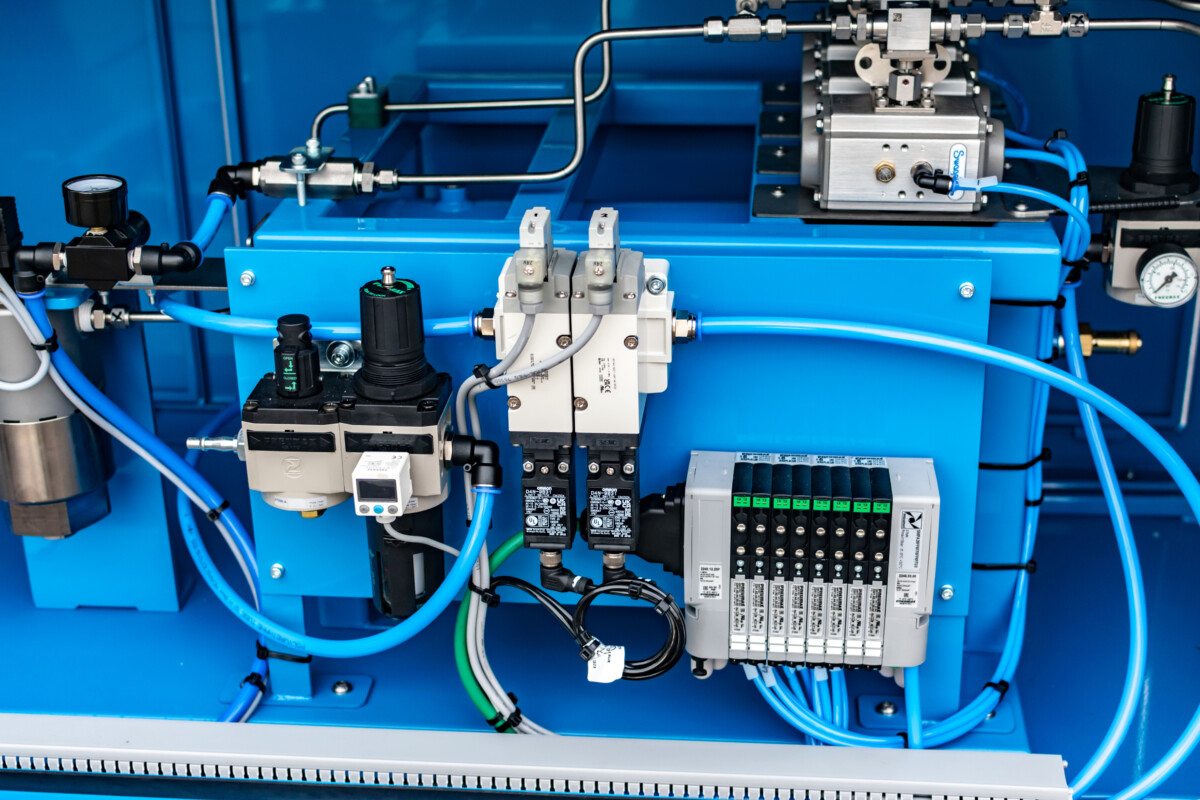

Commitment to Best Practice: Our facilities, equipment (including swaging machines and test rigs), and stock management are subject to detailed bi-annual technical audits by the BFPA. This ensures continuous adherence to the highest operational standards.

Don’t compromise on safety and quality. Partner with Rotec Hydraulics for your hydraulic hose assembly needs and Choose ‘Q’ for Quality.

For more information, or to place an order call 01823 348 900 or email sales@rotec.net.