Rotec Hydraulics Ltd, a leading provider of hydraulic, pneumatic, and electrical mechanical solutions, is pleased to announce its participation as an exhibitor at this year’s Seawork, Europe’s largest on-water commercial marine and workboat exhibition. The event will take place from 10th to 12th June 2025, at Mayflower Park in Southampton, UK.

Our team will be on Stand G38 showcasing Rotec’s comprehensive range of products and services tailored for the marine sector – with a particular emphasis on how to work smarter, reducing costs, whilst maximising performance and uptime.

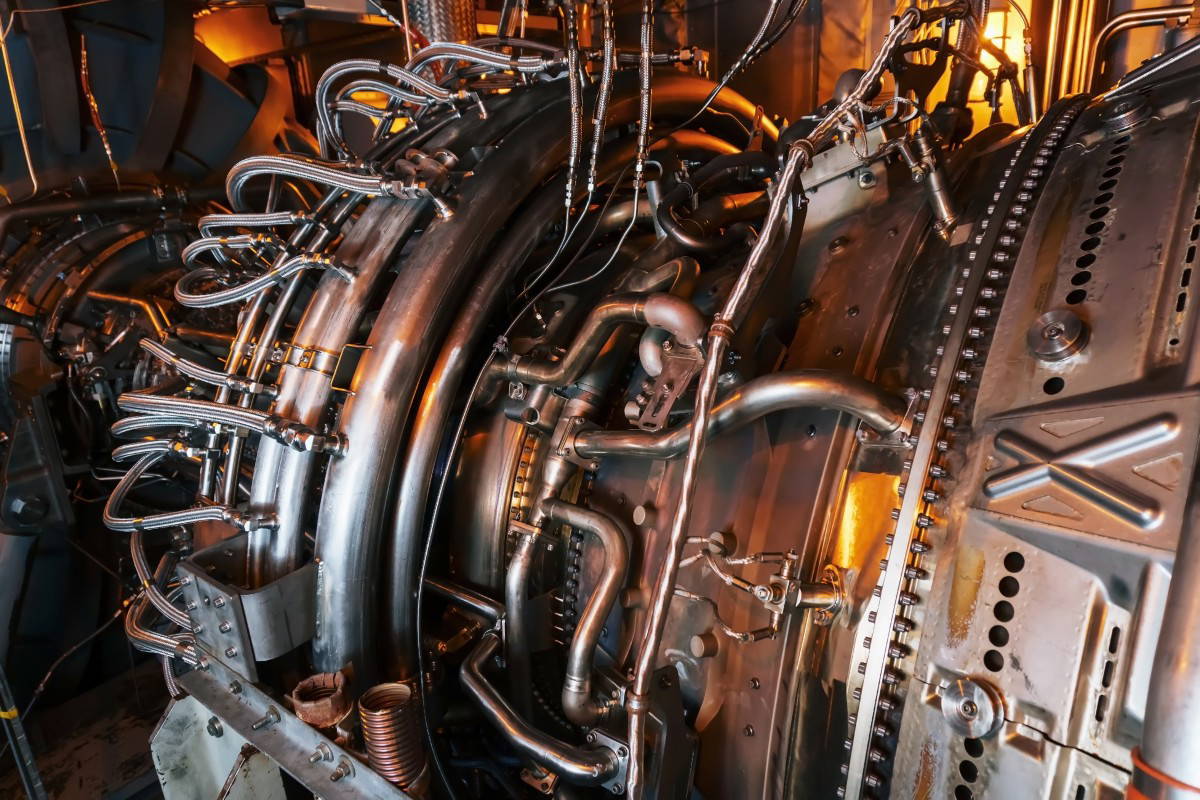

With over 40 years of experience, Rotec is renowned for its expertise in the design, build, supply, installation, and maintenance of fluid power and motion control systems.

Visitors to the Rotec Hydraulics stand will have the opportunity to explore:

- Bespoke Hydraulic and Pneumatic Systems: Discover Rotec’s capabilities in designing and manufacturing custom power units, flushing rigs, and complex system integrations to meet specific marine requirements.

- Electrical Mechanical Services (EMS): Learn about their comprehensive EMS offerings, including motor, alternator, generator overhauls, vital for marine vessel operations.

- PTS (Parker Tracking System): a barcode system that allows you to track assets worldwide and easily order replacements via a web based platform.

- IQAN: cutting-edge technology allowing for the monitoring and enhancing electrical control systems using the power of IoT.

- Component Supply: Explore Rotec’s vast stock of high-quality hydraulic and pneumatic components from leading brands such as Parker, Galtech, Heypac, and many more. Their team will be on hand to provide expert advice and technical support.

- Accumulator Servicing & Parts: Gain insights into stress-free accumulator management and PSSR compliance.

- OEM Kitting Service: See how Rotec’s custom multi-component kits and hose assemblies can streamline manufacturing processes and improve productivity.

The Rotec team will be available to discuss current projects, offer technical guidance, and explore potential collaborations with industry professionals.

“Seawork is a great event for the commercial marine industry, and we are delighted to be exhibiting again this year,”

says Richard Lang, Sales Director.

“It provides an invaluable platform to connect with our existing clients, forge new relationships, and demonstrate our commitment to delivering innovative and reliable solutions to the marine sector. We look forward to engaging with visitors and showcasing how Rotec can support your operations.”

Rotec invites all attendees to visit their stand at G38, Seawork 2025 to learn more about their capabilities and how they can assist with all fluid power and motion control needs in the marine industry.

Register to attend at: Seawork 2025