Rotec recently successfully completed a complex hydraulic system overhaul for a 430ft long ocean survey vessel. Working in collaboration with a leading ship repair and dry-docking partner in Cornwall, Rotec’s Falmouth-based engineering team executed a comprehensive cleaning, rebuild, and system flush of a critical Controllable Pitch Propeller (CPP) hydraulic system.

The project, which took place in December 2025, was defined by an incredibly demanding 10-day turnaround while the vessel was in dock. Despite the tight window, Rotec’s engineers ensured the system met and exceeded the rigorous standards required for Lloyd’s Register (LR) compliance.

Exceeding Technical Standards

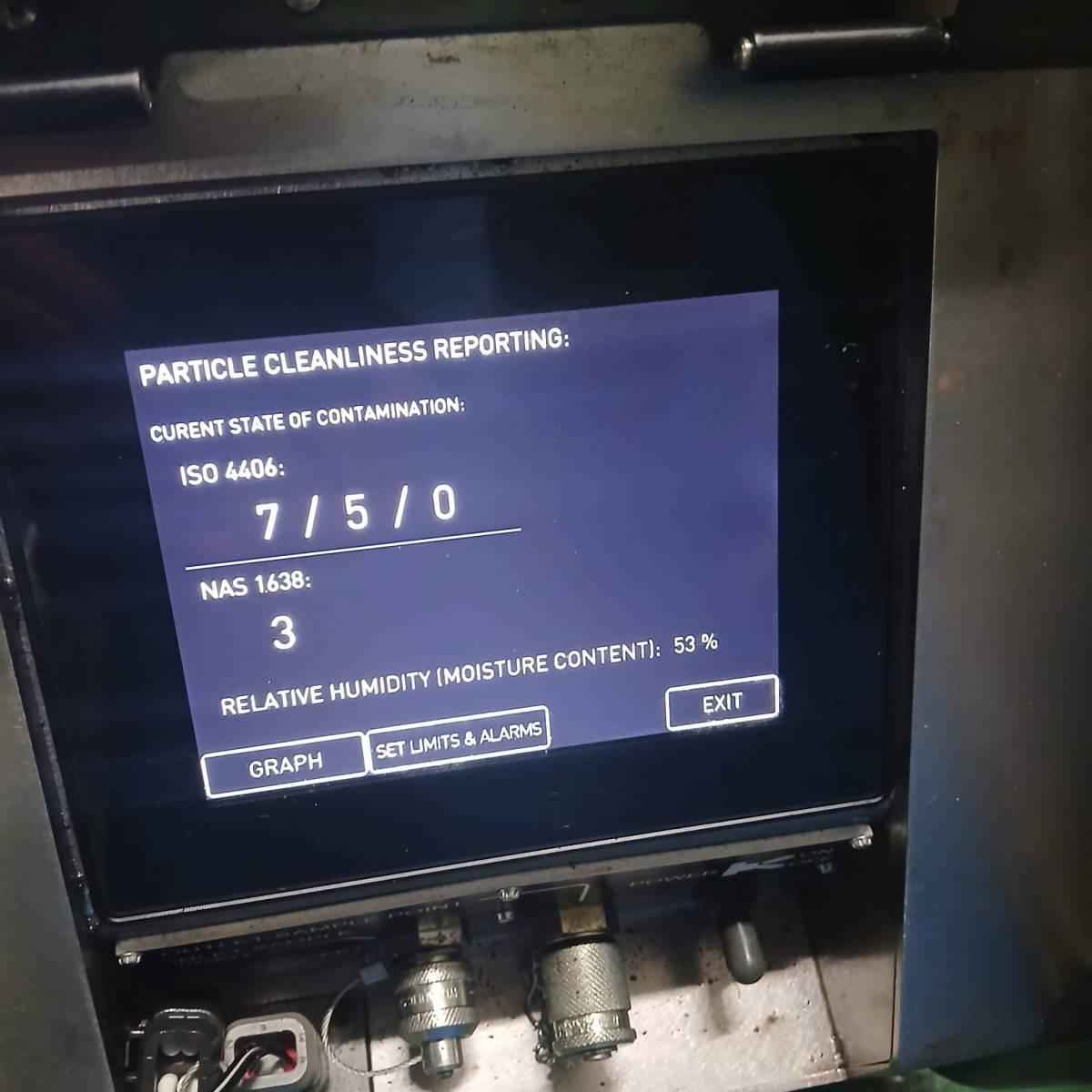

The primary objective was to eliminate foreign object debris (FOD), restore hydraulic cleanliness, and return the CPP circuit to a verifiable condition ready for functional testing. While the client specified a cleanliness standard of NAS 4, Rotec’s advanced mobile flushing and filtration technology, equipped with Parker IQAN real-time data logging, achieved a superior NAS 3 rating.

The scope of work included:

- Deep Cleaning: All CPP rod sections and shaft tubes were initially manually cleaned and pigged to remove visible contamination.

- Precision Flushing: Each rod and tube section flushed using heated hydraulic oil (at phases of 40°C and 60°C) through multi-stage filtration down to 2 microns.

- HPU Restoration: Stripping, cleaning, and flushing the Hydraulic Power Unit (HPU) and associated pipework.

- System Rebuild: Full shaft rebuild and system charging in accordance with OEM instructions and surveyor guidance.

The Falmouth depot team worked around the clock to ensure the vessel was hydraulically complete and ready for commissioning. Following the successful venting and oil charging to the header tank, the system was approved by both Ministry and Lloyd’s representatives.

Martin Webber, Rotec’s Falmouth Depot Manager, commented:

“This project was a true testament to the skill and dedication of our Falmouth team. Managing a full CPP shaft and HPU rebuild within a 10-day docking window requires planning and precision. By utilising Rotec’s specialised, custom-designed portable flushing rigs, we didn’t just meet the client’s cleanliness targets—we exceeded them, delivering a NAS 3 standard that ensures long-term system reliability for the vessel.”

Optimise Your Fleet’s Performance

Rotec’s portable flushing rigs with IQAN technology are available for hire, providing live, verifiable data to ensure your hydraulic systems meet the highest international cleanliness standards.

To enquire about our marine engineering services or equipment hire, contact the Rotec team today.