HPU for a Apecial Alloys Producer

Rotec was commissioned to manufacture a Hydraulic Power Unit for a British high-nickel alloy specialist. The customer produces special metals for a variety of industries including Aviation, Automotive, Marine, Oil & Gas and more. The project was referred to Rotec by another hydraulic engineering company.

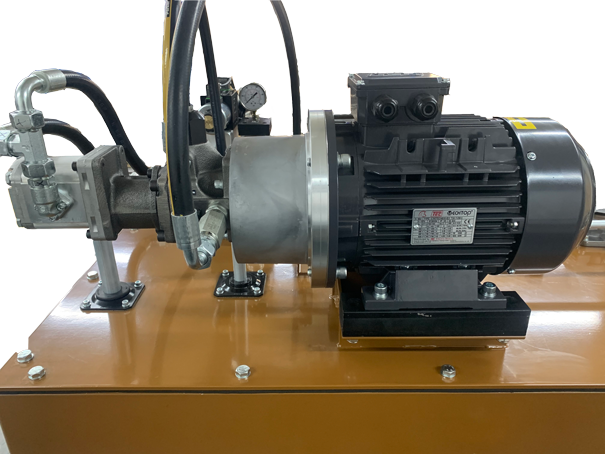

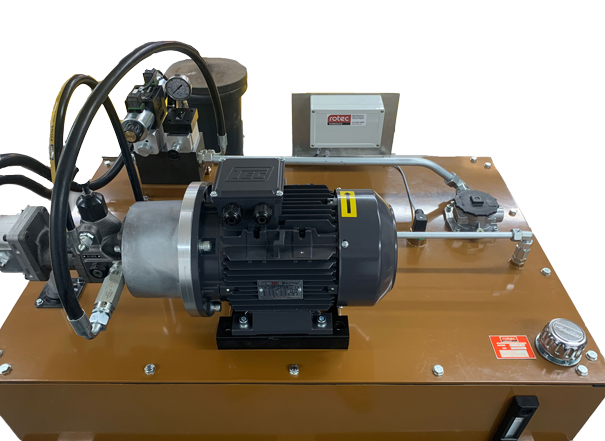

Rotec produced a double pump arrangement with the main pump working at 23 LPM and pump 2 at 27 LPM. This design provides a regenerative flow to the cylinder where when the cylinder is extending, it’s using the flow from the annular side of the cylinder directed to the bore side to make the cylinder extend faster, to allow a faster production rate. The HPU drives a hydraulic cylinder which pulls lengths of hollow bar over a cutting tool to machine the inside diameter of the bar. A new unit was required, to replace an old existing one which was leaking oil and was inefficient.

Rotec designed and built the unit working to an existing hydraulic circuit drawing supplied by the customer. The unit is designed to withstand the tough working conditions of a busy foundry and includes a bundt which helps contain any leaks during maintenance.

The unit has now left Rotec’s workshop and is ready for installation.

Technical Specs:

- Main Pump: 23LPM

- Pump2: 27LPM

- Working pressure: 27 Bar

- Electric motor: 4kW

- 450 litre reservoir and 495 litre bundt