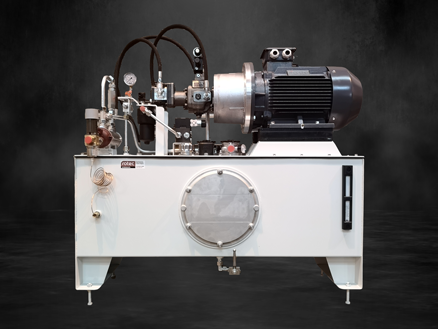

HPU with a 250 litre reservoir

Project background: How did we get this project. What is the unit used for? (Richard Lang or Dale Lockart can find out)

- Technical Specifications:

- The HPU consists of a 250 litre reservoir.

- 5kW 6 pole electric motor

- Bell housing and Starex type coupling

- Double Pump:

- Berarma variable delivery vane pump with a maximum displacement of 16cc/rev, which has been de-stroked to 9 cc/rev to deliver 8 lpm at 950 rpm

- Coupled to the back of the Berarma pump is an Elika group 2 gear pump of 11.4 cc for the conditioning system which will deliver 11 lpm of flow through the system

The Berarma vane pump is a pressure compensated design with high pressure cut off control and a high pressure setting of 230 Bar (When the pump is dead headed against the pressure port closed servo valve and producing Zero flow, the pump pressure is 230 Bar, producing up to 8 L/min up to 210 Bar dynamically). The pump is also fitted with an integral pump un-load valve (24vdc single solenoid, 2 position spool control directional control). This will be to unload the main variable delivery pressure compensated pump to its minimum pressure setting of 25 Bar when the solenoid is de-energised.

The main relief will be set to 260 Bar. Also included is an analogue pressure gauge, inline check (non-return) valve and 2 micron pressure filter with electrical indication switch. A second electrical unloading solenoid valve will be fitted downstream of the check valve and filter to facilitate unloading of hydraulic pressure when the unit is turned off.

From the Elika gear pump, the conditioning system will have a shell and tube type heat exchanger and a second, 10 micron tank top filter. A 4.5 Bar check (non-return) valve will be installed as a bypass relief valve to protect the heat exchanger. A temperature-controlled water solenoid valve will be fitted to regulate the flow of cooling water through the heat exchanger.